Electronics manufacturing services

Electronic manufacturing services are part of our deep customer service

IATF16949

ISO4001

ISO9001

ISO13485

As a comprehensive solution provider in the electronics manufacturing industry, we provide customers with comprehensive electronic product processing and OEM manufacturing services. Especially when start-up R&D companies and small enterprises lack manufacturing and supply chain resources, we can integrate resources for customers. And provide one-stop service for products.

We work closely with a number of industry-leading EMS manufacturers to provide comprehensive technical support from design to manufacturing. Our services include the design and manufacturing of electronic product components, industrial parts supply and product realization. We always keep our customers' needs at the core, ensuring that the most suitable manufacturing service provider is selected to meet specific requirements.

Our experienced global supply chain team focuses on reducing costs and delivery times, ensuring material availability and continuity of supply, while strictly adhering to quality standards. We are committed to obtaining quality materials at the lowest cost and ensuring on-time delivery. Our engineers and professional technicians will deeply analyze your needs and provide practical solutions that exceed your expectations.

We not only provide excellent quality, but also strive to provide customers with the best service experience, helping them focus on their core business and drive business growth. Our goal is to help customers achieve success in a rapidly changing market environment through integrated solutions. We look forward to working with you to create a better future together.

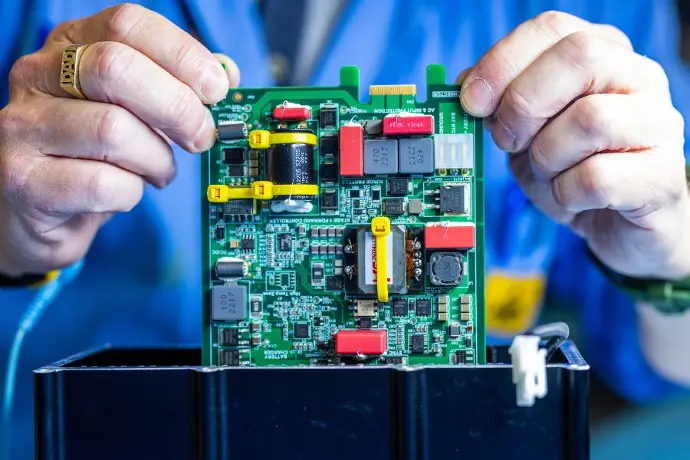

Factory capacity

Our partner factories are equipped with industry-leading production and testing equipment to ensure efficient and reliable electronic product manufacturing. It has more than 21 ASM Chip placers and a variety of supporting equipment from the world's top brands, such as printing machines, SPI, AOI, reflow ovens, wave soldering and laser engraving machines. In terms of testing equipment, we have X-ray, flying probe testing, Agilent 3070 ICT, BGA rework station, salt spray testing and other equipment to ensure the quality and reliability of products.

In terms of process capabilities, we are able to carry out mass production of 01005 patches, BGA mounting, water washing, conformal paint coating, etc. The minimum patch pin spacing is 0.3mm, and the board size can be up to 610mm x 580mm, with a thickness of 5mm.

Our management team is composed of professionals from first-class EMS companies with rich manufacturing and management experience and the ability to communicate smoothly with overseas customers. We adhere to the customer demand-oriented CFT management model, provide efficient professional services, and ensure customer satisfaction. We look forward to working with you to advance your business.

Factory advantage

With advanced equipment and a professional team, we have complete process capabilities and a complete quality control system. Our global supply chain is maturely integrated, our R&D capabilities are continuously optimized, and we adopt the CFT (Customer Focus Team) management model. The management system includes ERP, MES, ISO9001, ISO14001, ISO13485, IATF16949, etc., and cooperates with the visual management system and process traceability system to ensure efficient production and service quality.

Main customer product application areas

Automotive industry

Industrial control industry

Medical industry

New energy industry

Consumer electronics